![]()

Spark Gap Experiments

UPDATED: February 20, 2006

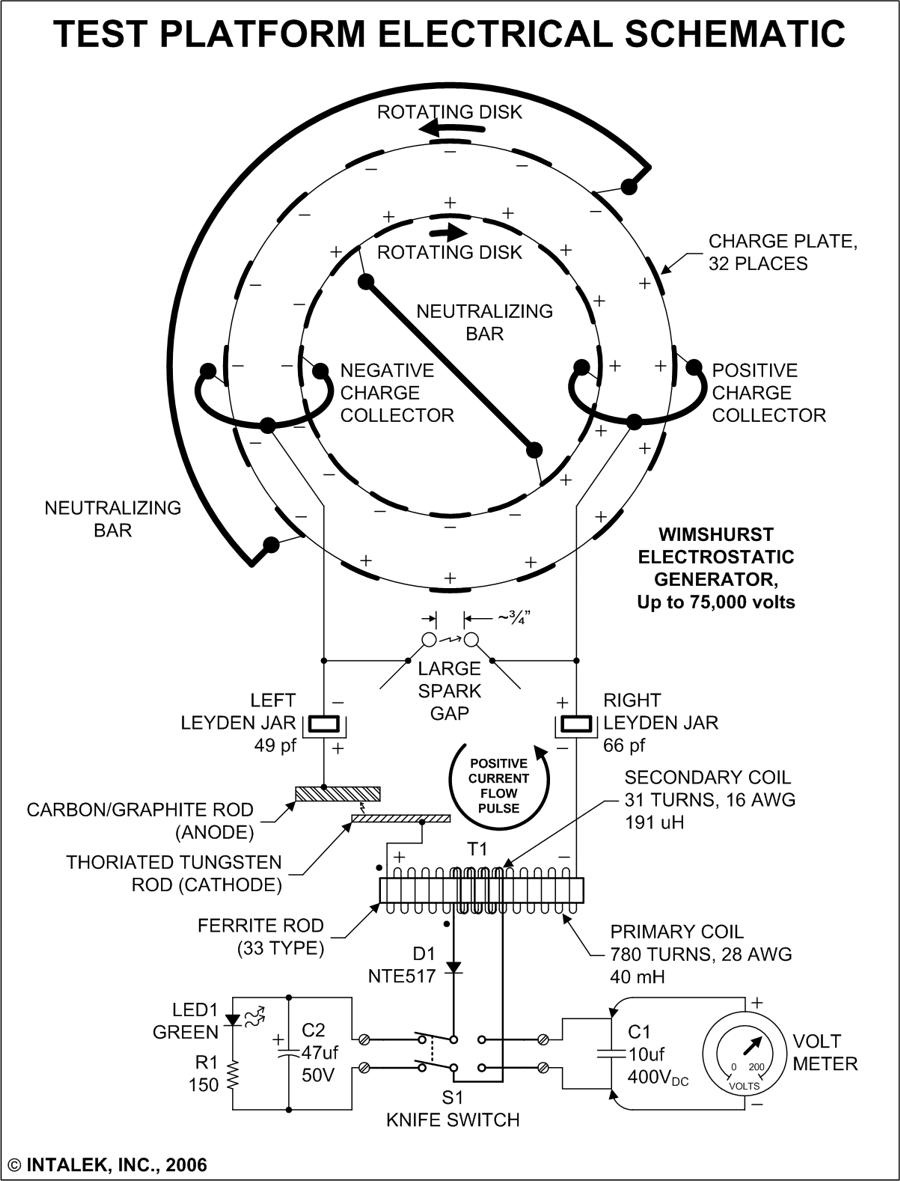

Excess electrical energy has been discovered in spark gaps using Carbon/Graphite - Thoriated Tungsten rods with a Coefficient of Performance (COP) greater than 100% across the gap. A Wimshurst Generator is used as a primary high-voltage dynamo. A Tesla-like step-down transformer T1 with a ferrite rod is used to efficiently reduce the high-voltage down to safe practical levels, which can easily be distributed and measured. As shown in Fig. 1, successive electric discharges or Electrum Validum (EVs) discharges are generated, and their associated energy is collected in a 10uf low loss capacitor during a given period of time.

The energy stored in a capacitor is calculated as follows:

E = ½ C V²

Where,

E is the energy stored in the capacitor.

C is the capacitance.

V is the voltage across the capacitor.

The Wimshurst Generator used in this experiment is capable of generating voltages up to 75,000 volts, and is available from Edmund Scientific.

Figure 1. Spark gap experiments using the Wimshurst Generator.

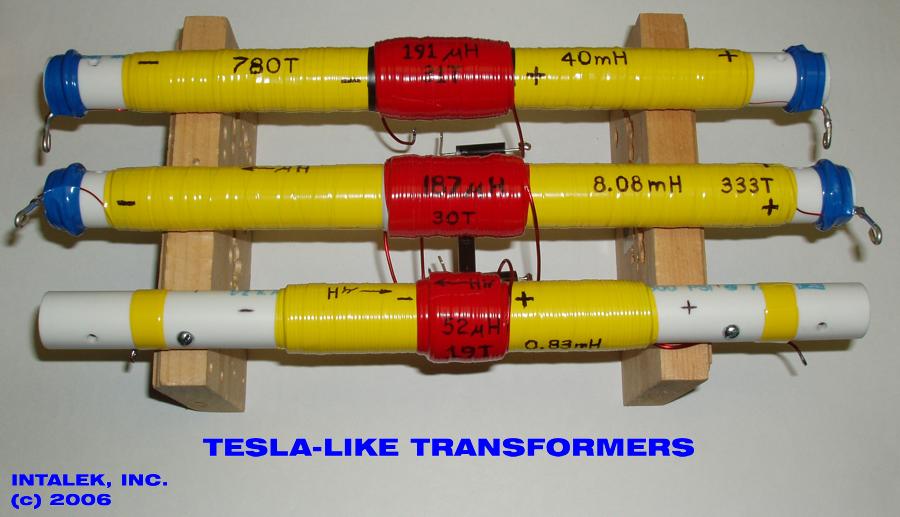

Fig. 2 details the spark gap test platform. Above center-left shows the spark gap where excess electrical energy is observed. This energy is transferred through a Tesla-like step-down transformer T1 where the single layer primary winding of the transformer is shown in yellow and the single layer secondary winding is shown in red. Its imperative to use single layering because it minimizes electric arcing. A ferrite rod is used in this transformer to improve efficiency by increasing its' overall inductance. A knife switch is used to direct the flow of energy to either a capacitor or a LED display.

Figure 2. Detail of the test platform.

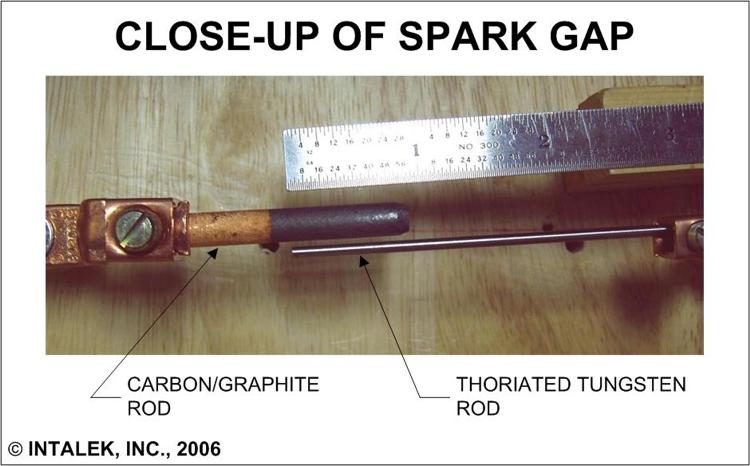

Figure 3. Close-up view of Carbon/Graphite - Thoriated Tungsten spark gap.

Figure 4. A variety of Tesla-like transformers are tested.

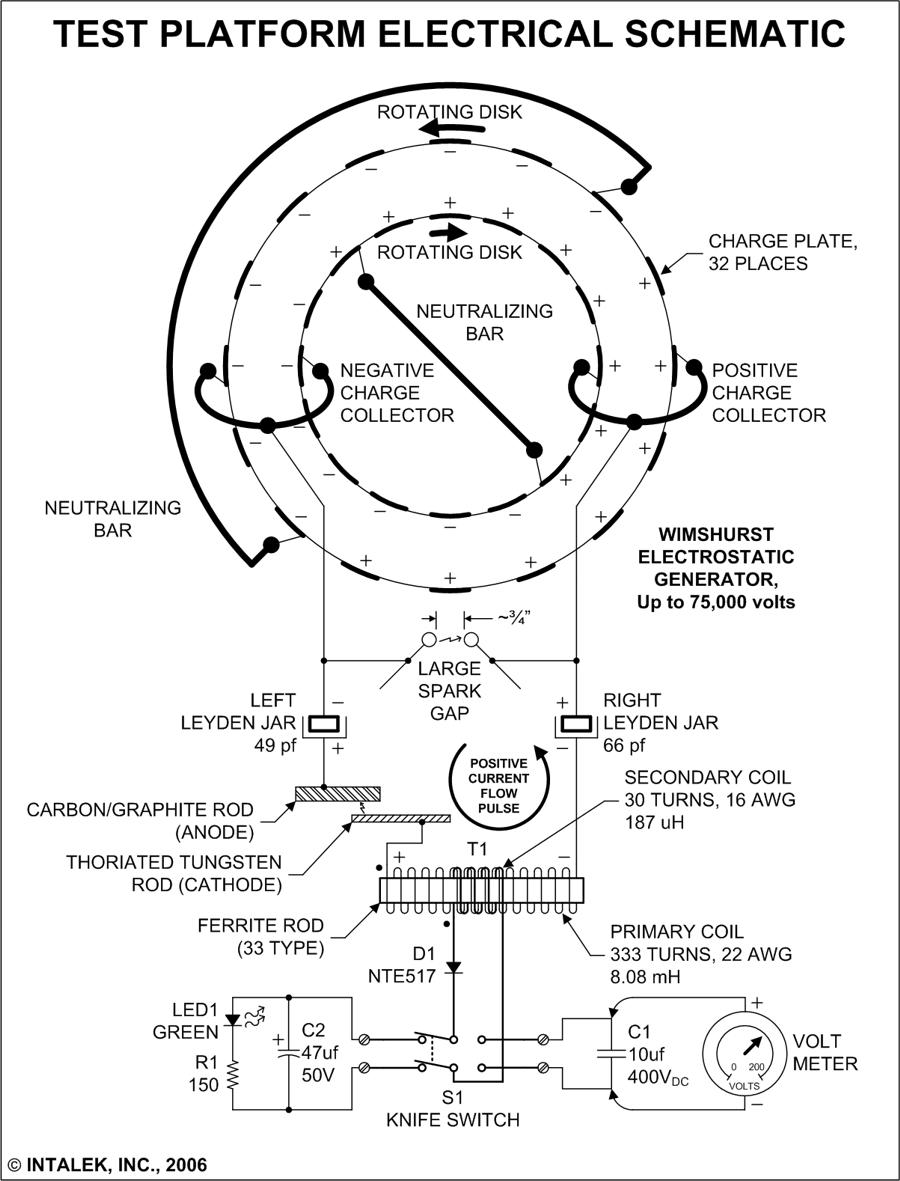

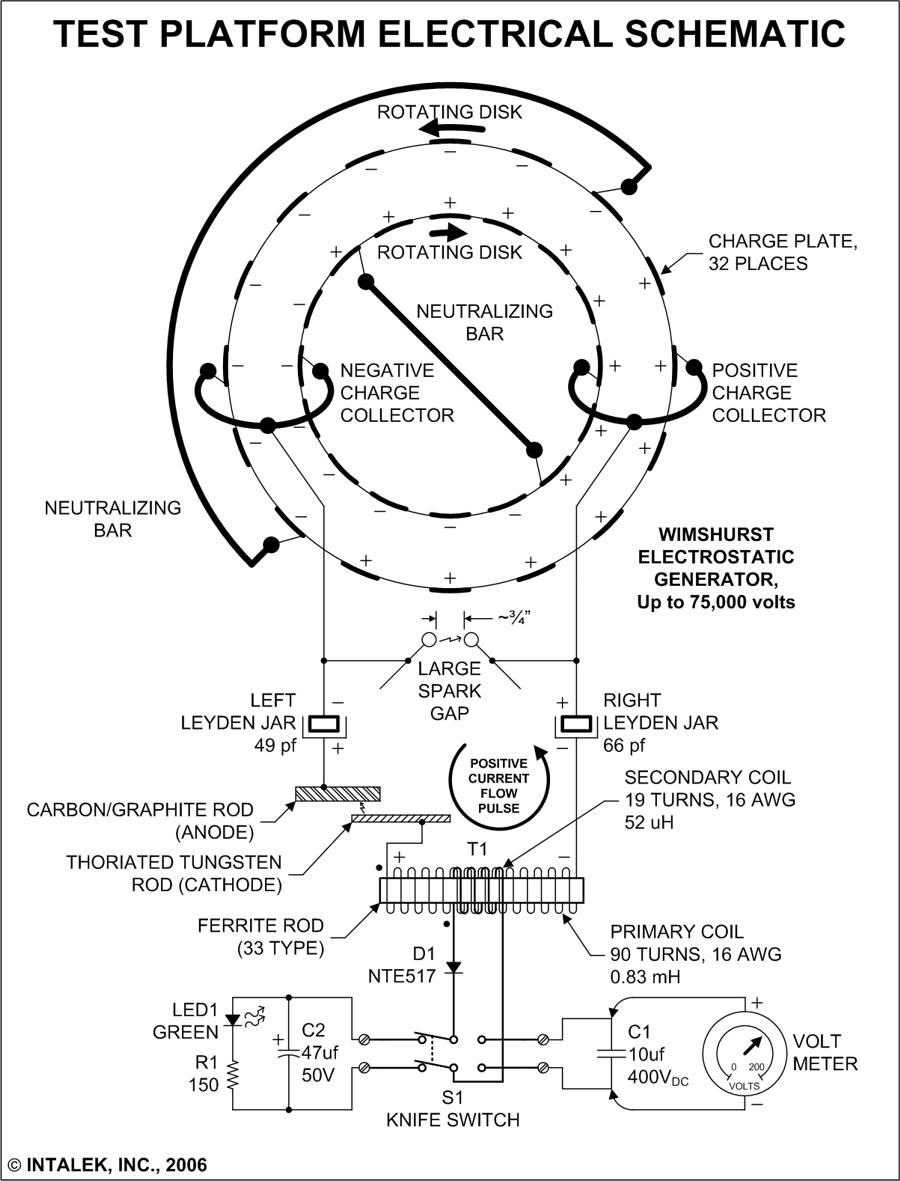

Fig 5. shows the electrical schematic of the test platform. A high electrostatic voltage is generated by counter-rotating disks and the energy that's collected is stored in Leyden Jars. This stored energy is discharged through a large spark gap with a gap width of approximately 3/4", as shown. The circuit is completed by connecting the Carbon/Graphite - Thoriated Tungsten spark gap rods and the Tesla-like transformer T1 to the base of the Leyden Jars.

Figure 5. Wimshurst Generator test platform electrical schematic using 333 turn primary.

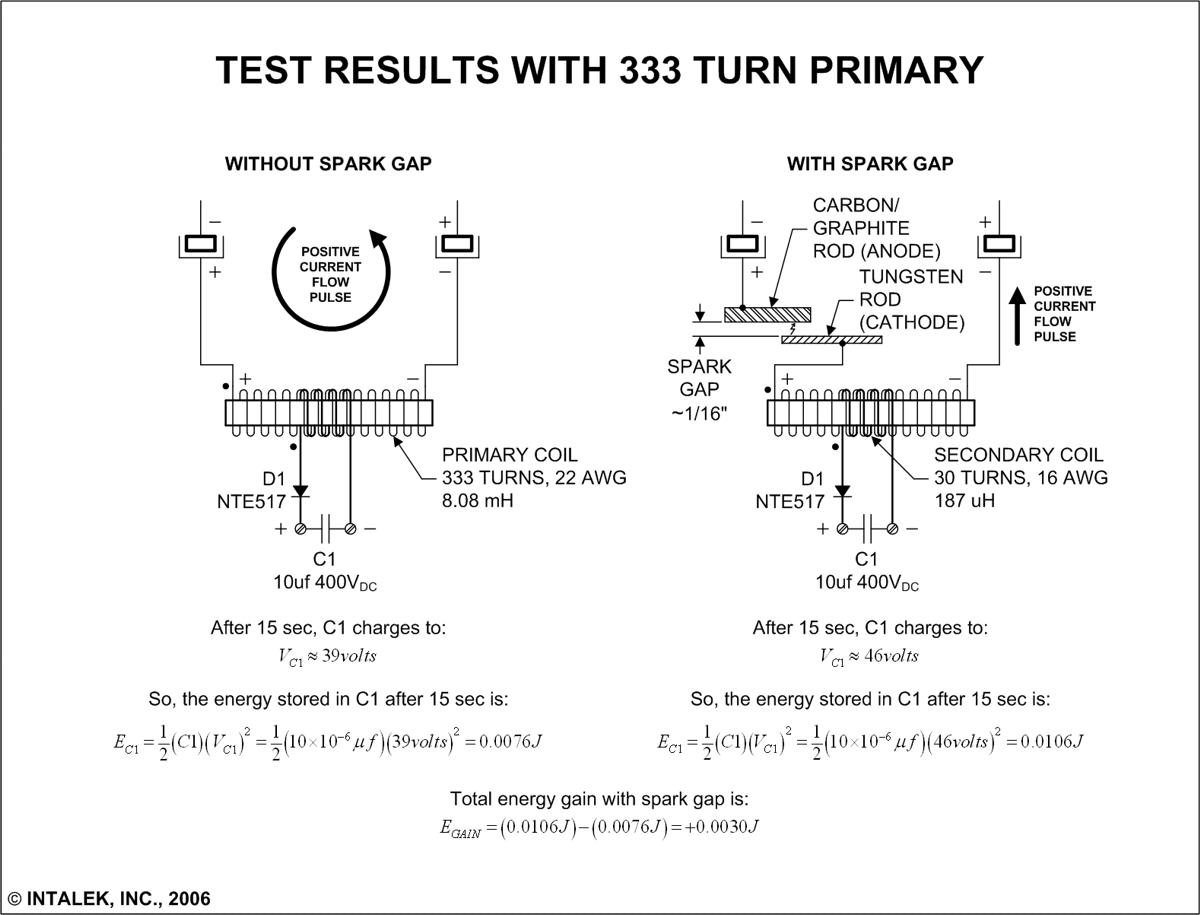

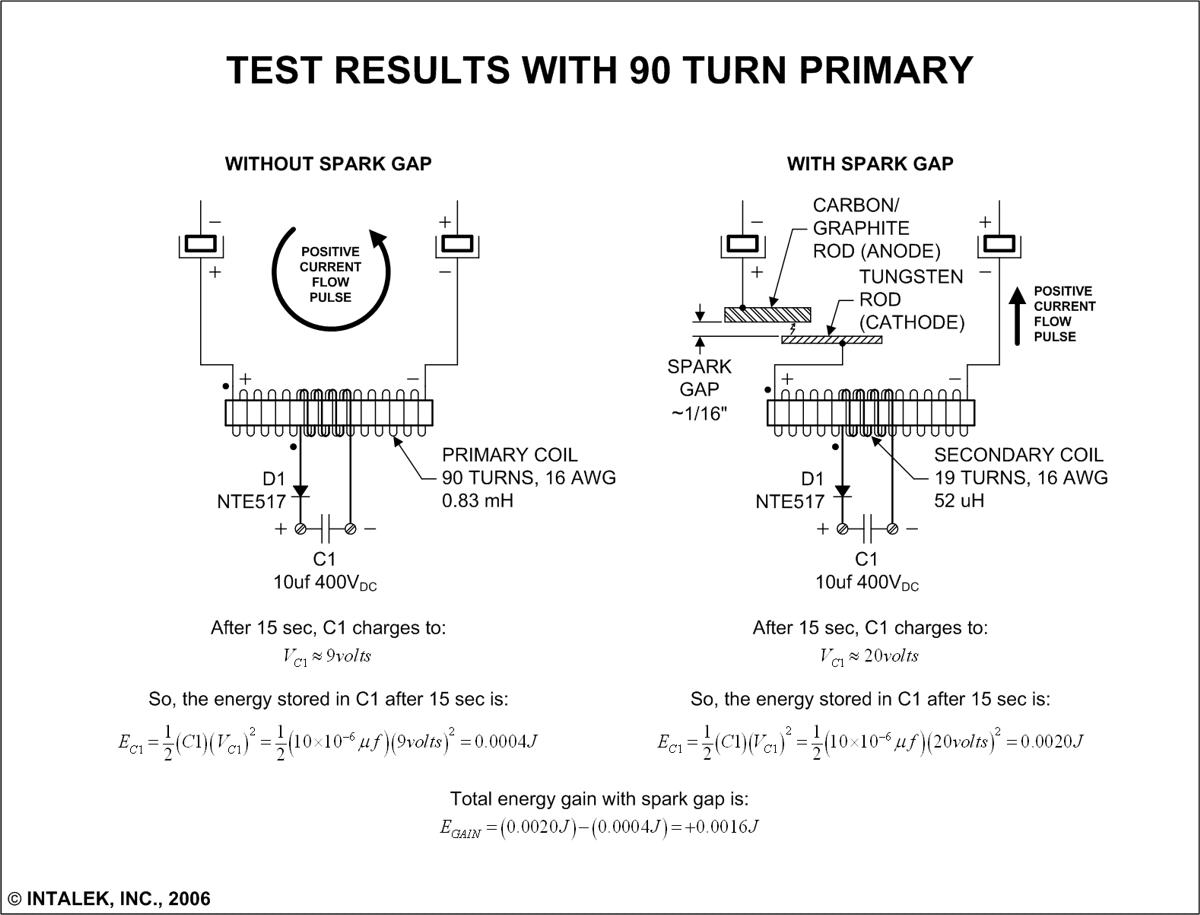

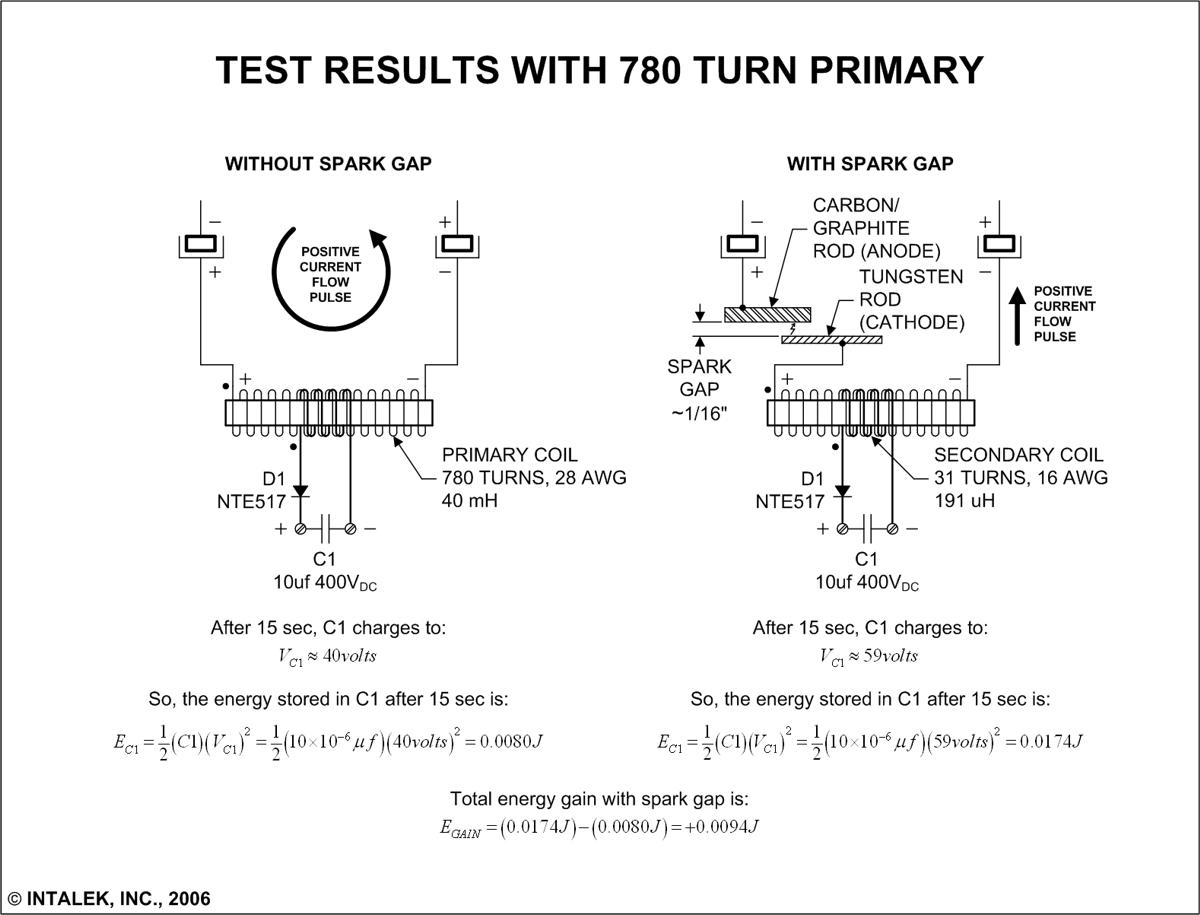

Fig. 6 details the spark gap test results. The Wimshurst Generator is operated for a time period of 15 seconds. At the end of this period, the voltage across capacitor C1 is logged. The test platform is operated with and without the Carbon/Graphite - Thoriated Tungsten rod spark gap, and the resulting voltage is logged.

Figure 6. Test results using 333 turn primary.

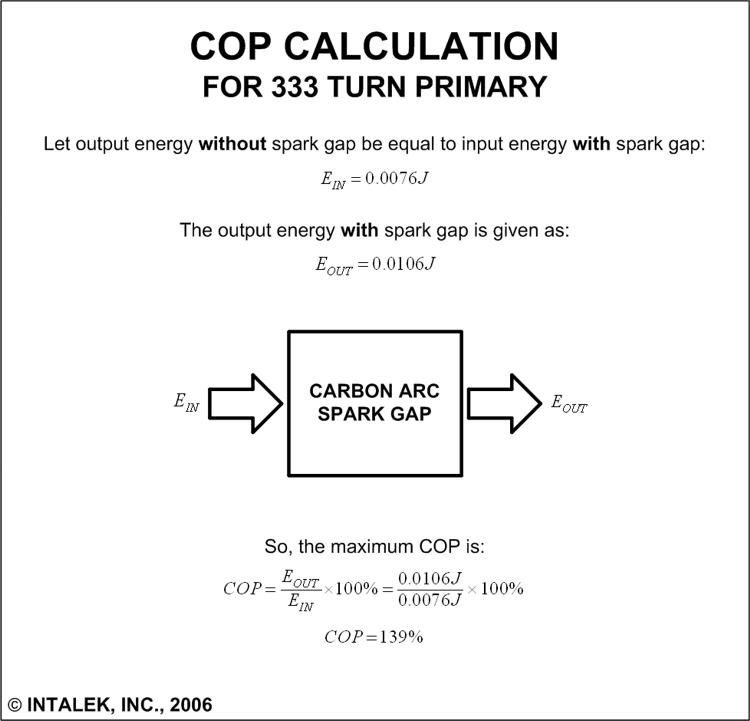

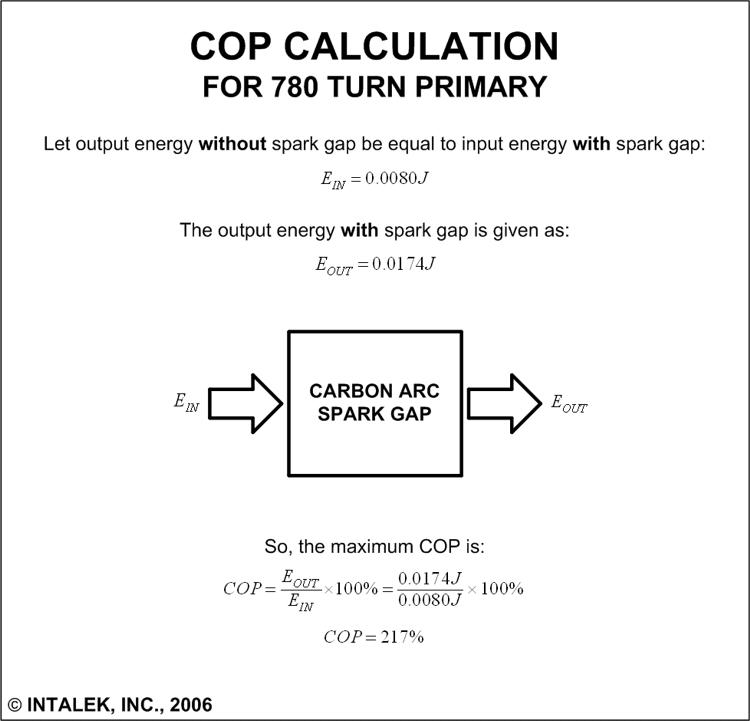

Knowing the energy stored in the capacitor C1 and assuming an ideal system, its possible to calculate the Coefficient of Performance (the COP) as shown below. The maximum COP is 139% as shown in Fig. 7.

Figure 7. The COP calculation for 333 turn primary.

Figure 8. Wimshurst Generator test platform electrical schematic using 90 turn primary.

Figure 9. Test results using 90 turn primary.

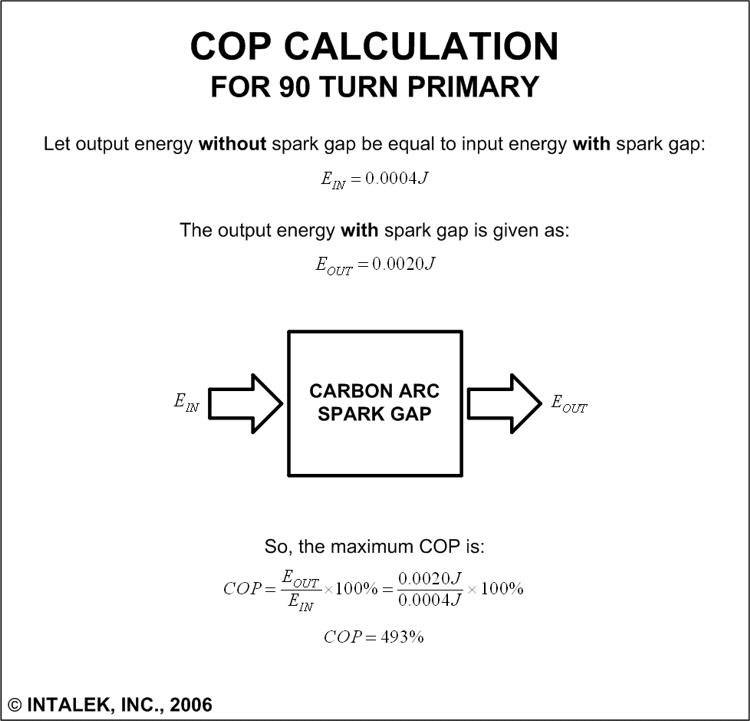

Figure 10. The COP calculation for 90 turn primary.

Figure 11. Wimshurst Generator test platform electrical schematic using 780 turn primary.

Figure 12. Test results using 780 turn primary.

Figure 13. The COP calculation for 780 turn primary.

My conclusion is the Carbon Arc is performing as a NEGATIVE resistance-like device in every test case. The bottom line is that there is MORE energy charging up capacitor C1 with the spark gap than without, and the greater the primary inductance, the greater the amount of energy that is collected. Therefore, the Carbon Arc looks very promising as providing excess energy, once properly harnessed.

Go to Multi-Spark Gap Experiments page

MORE INFORMATION